Ukudala ubuciko bengilazi eshintshile kungaba nzima, ikakhulukazi kwabaqalayo. Ukukhetha i-foil yethusi engcono kakhulu kunqunywa yizici eziningana njengosayizi nobukhulu be-foil. Okokuqala awufuni ukuthola i-foil yethusi engahambisani nezidingo zephrojekthi.

Amathiphu okukhetha i-copper foil efanele

Ngenhlanhla,Insimbi Ecijileinemininingwane emihle ewusizo lapho uthenga i-foil yethusi efanele kodwa elula ukuyisebenzisa kuphrojekthi oyenzayo. Yiziphi ezinye zezinto ezibalulekile okufanele uzicabangele lapho ukhetha i-foil yethusi efanelekile yengilazi eshintshile umbala? Sizobheka ezinye izinto okufanele uzicabangele ngaphambi kokuthenga i-foil yethusi engcono kakhulu yephrojekthi yengilazi engcolile.

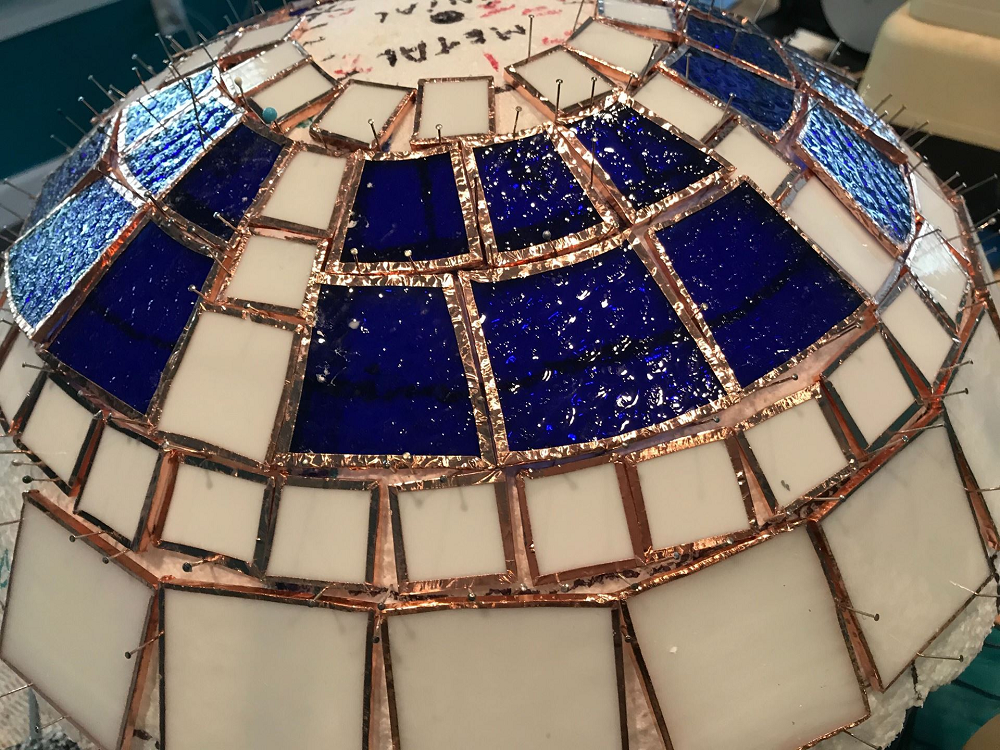

Usayizi wephrojekthi

Usayizi wephrojekthi unquma usayizi we-foil yethusi efanelekile ukusetshenziswa. I-foil yethusi engu-3/16″ noma 1/4″ ilungele ukusetshenziswa kwengilazi. Ama-foil abanzi kakhulu kunalolu hlu ngokuvamile ayaba nzima uma ufaka. Ngisho noma esetshenziselwa amaphaneli amakhulu engilazi, ama-foil abanzi awasebenzi kahle. Uma ubheka usayizi wephrojekthi okhona kubalulekile lapho ukhetha i-foil yethusi efanele yengilazi eshintshiwe. I-Civec Metal inikeza ama-foil ethusi osayizi abahlukene ukuze ahlangabezane nawo wonke amaphrojekthi.

Ububanzi befoyili yethusi

Ama-foil ethusiokushiya imigqa emincane ingasebenzi kahle futhi iqinile. Lokhu kungenxa yokuthi i-solder eyengeziwe ingasetshenziswa ensimbini. Iningi labaculi likhetha ukusebenzisa i-foil engu-7/32″ kodwa uma kwenzeka ushintsha ububanzi be-foil yethusi, kudingeka ukujula okwengeziwe. Ingilazi ejiyile kakhulu idinga i-foil yobubanzi obungu-¼”. Ukuze usebenzise imiphumela eyengeziwe, kuwukuhlakanipha ukusika i-foil usebenzisa i-razor blade ebukhali. Futhi, ukwakha ibanga kuphrojekthi yakho yomsebenzi akunzima njengoba imigqa ye-foil iyancipha ngokuhamba kwesikhathi. Ukuze ufeze lokhu, i-foil engu-5/32″ noma engu-3/16″ ilungele uma ungeza ukuthinta kokugcina.

Ubukhulu befoyili yethusi

Ifoyili yethusingokuvamile kulinganiswa ngokwe-mils. Qaphela ukuthi ama-foil ethusi ashibhile avame ukuguguleka kalula, ikakhulukazi uma efakwe emakhoneni. I-foil yethusi yokuqala nekhwalithi ayidabuki ngakho-ke ilungele amaphrojekthi engilazi. I-foil yethusi encane kakhulu ingu-1 mil kodwa amaphrojekthi amaningi engilazi adinga i-foil engu-1.25 mils. Lolu hlobo lwe-foil luyakwazi ukudabuka futhi lufanele ukufakwa ezindaweni zengilazi ezigobile.

Uhlobo lombala wesisekelo

Ama-backback e-copper foil atholakala ngemibala emithathu ehlukahlukene; omnyama, isiliva, kanye nethusi. I-backback efanelekile yombala idinga ukuhambisana nombala wombala we-copper foil ozosetshenziswa. Kwi-patina yethusi, i-foil ene-copper-backed ingcono kakhulu ekufakweni. Ezinye izibuko ezifana ne-opalescent azidingi i-backback yombala othile ngoba kunzima ukuyibona i-backback. Izibuko ezikhanyayo zidinga i-backback ehambisanayo ukuze ivelele futhi ibonakale. Umbala wengilazi udinga ukuhambisana nengilazi ukuze uveze ukukhanga.

Umklamo wephrojekthi

Umklamo wephrojekthi udlala indima ebalulekile lapho kungezwa izifiso zomuntu siqu kanye nezintandokazi. Imigqa esindayo kuphrojekthi idinga i-foil ebanzi kakhulu. I-foil encane inhle kakhulu ekuhlinzekeni umklamo wephrojekthi olula.

Ukubonakala kwengxenye yengilazi

Ukusebenzisa ububanzi obuhlukene be-foil yethusi engilazini eshintshile umbala kunikeza ukugcizelela okwengeziwe, ikakhulukazi lapho kune-foil esindayo. Okuphawulekayo ukuthi i-foil inikeza imininingwane eyengeziwe ngokuhlukanisa ingemuva nengaphambili. Futhi, kungenzeka ukwengeza isihloko ngenkathi udonsela ukunaka okukhulu engxenyeni yengilazi.

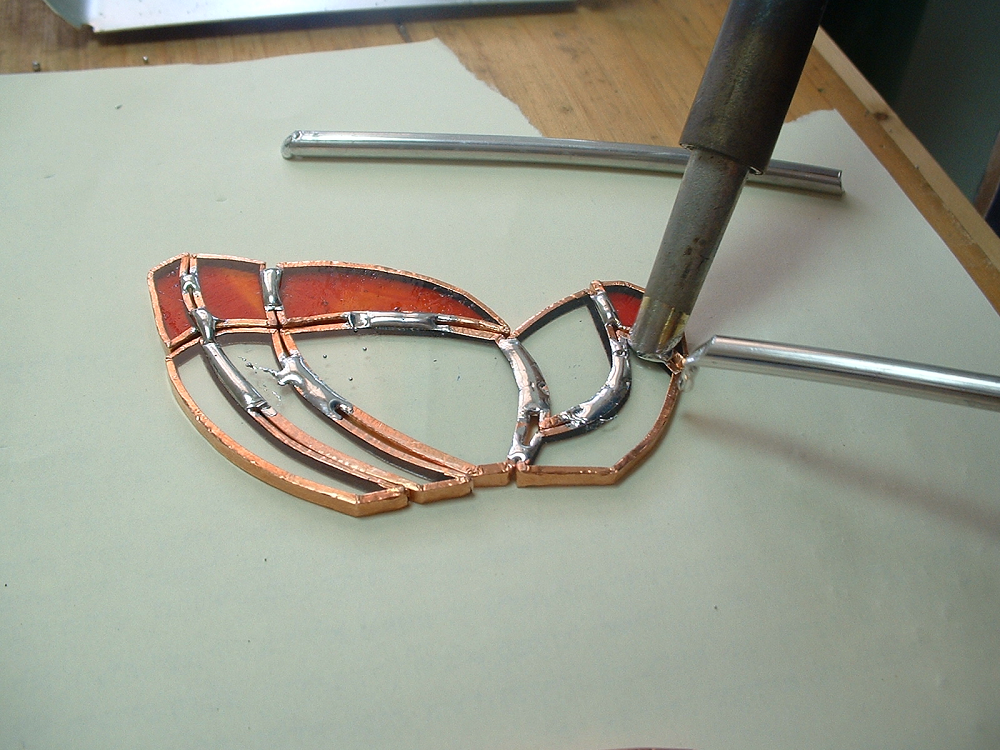

Indlela yokubopha ama-foil usebenzisa ama-foil ethusi

Ukuze uqale ukufaka ifoyili, okokuqala, bopha ifoyili kude nomphetho wobuso bephrojekthi. Lokhu kwenza ukuxhumana phakathi kwengilazi eshintshile umbala namafoyili kuqine. Lokhu kungenxa yokuthi ifoyili ayixhunyanisiwe nomphetho lapho ingase ikhululeke khona. Uma ufaka ifoyili, hlola imigqa enezinombolo yengxenye yephrojekthi bese uqala lapho ukuze uthole ukunamathela okufanele.

Gwema ukunamathela kancane njengoba i-glue ivame ukuncibilika futhi ngaleyo ndlela ingabambeki. Inhloso ye-glue ukugcina i-foil ingashintshi kuze kube yilapho inamathela ekugcineni. Futhi, lungisa ububanzi be-foil yethusi yangaphandle ukuze uqinise ukuqina kwe-solder.

I-Ra yethusi foil

I-Ra copper foil inhle kakhulu uma kudluliswa ama-copper foil ngama-roller amabili. Lokhu kwenza i-copper foil ikwazi ukuthola ubukhulu obufanele kakhulu iphrojekthi. I-Ra copper ibushelelezi ngokwemvelo ngakho-ke iguquguquka kakhulu, ikakhulukazi uma ijikeleza ezindaweni zokusebenza ezigobile. Okubalulekile, ubulukhuni bama-copper foil buyashintsha ngenxa yezici eziningana ezifana nokucindezela kwama-roller.

Izici ze-foil yethusi esezingeni eliphezulu

Ama-foil ethusi asiza ukuxhuma izibuko ngokusebenzisa i-solder. I-solder ayibambeki uma ithintana neklasi yingakho kudingeka i-foil yethusi futhi isebenza njengesisekelo. I-Cevic Metal inikeza ama-foil ethusi asezingeni eliphezulu kodwa asezingeni eliphezulu analezi zici.

·Ukuguquguquka: I-foil yethusi esezingeni eliphezulu idinga ukusebenza kahle kakhulu ezindaweni ezigobile. Ngalokhu, sisho ukuthi i-foil kufanele yelulwe ngomzamo omncane ukuze ilingane kahle engilazini ngaphandle kokudabula. Ama-foil ethusi ezingilazini ezingcolile kufanele futhi abe lula ukuwasebenzisa lapho uyifaka.

·Ubumnene: I-foil idinga ukuba thambile ukuze inwebeke kahle ebusweni bephrojekthi. Ama-foil ethusi athambile avumelana kahle nesimo sengilazi uma kuqhathaniswa nama-foil aqinile. Okubalulekile, akuwona wonke ama-foil athambile angcono kakhulu. Singumthengisi osemthethweni wazo zonke izidingo zephrojekthi yeglasi ikakhulukazi lezo ezidinga ama-foil ethusi athambile.

·Amandla: I-foil yethusi efanelekile idinga ukuqina futhi inamathele kahle ekufakweni. Ama-foil aqinile asebenza kahle ngenkathi esusa noma yikuphi ukukhinyabezeka.

Ukugcina i-foil yethusi isikhathi eside

Ama-foil ethusi asengozini yokuhlaselwa yizimo zemvelo futhi ukuwavikela kubalulekile. Ukuvikela ama-foil ethusi kusiza umuntu ukuthi agweme izindleko ezihlobene nokuthola okunye. Lena yindlela ongayandisa ngayo impilo ye-foil yethusi.

·Gcina ama-foil ethusi endaweni epholile neyomile. Isikhwama esingangeni moya siyindlela efanelekile yokusebenzisa isikhathi eside.

·Ukuzifaka emathinini angangeni moya kuvimbela umswakama ukuthi ungaphazamisi ukubukeka kanye nekhwalithi ye-foil yethusi.

I-Cevic Metal inikeza ama-foil ethusi angafani nhlobo afanelekela kokubili imisebenzi yobuciko kanye neyezimoto. Yonke imikhiqizo enikezwayo ihlala isikhathi eside uma iqhathaniswa nama-foil ethusi avamile.

Isikhathi sokuthunyelwe: Julayi-05-2022