Njengoba ikhanga kakhulu emikhiqizweni ehlukahlukene yezimboni, ithusi libhekwa njengento eguquguqukayo kakhulu.

Ama-foil ethusi akhiqizwa ngezinqubo zokukhiqiza ezithile ngaphakathi kwe-foil mill okuhlanganisa kokubili ukugoqa okushisayo nokubandayo.

Kanye ne-aluminium, ithusi lisetshenziswa kabanzi emikhiqizweni yezimboni njengento eguquguqukayo kakhulu phakathi kwezinto zensimbi ezingenayo i-ferrous. Ikakhulukazi eminyakeni yamuva nje, isidingo se-copper foil besilokhu sikhula ngemikhiqizo kagesi ehlanganisa omakhalekhukhwini, amakhamera edijithali, namadivayisi e-IT.

Ukwenziwa kwefoyili

Ama-foil ethusi amancane akhiqizwa ngokubeka i-electrode noma ngokugoqa. Ukuze kube nokubeka i-electrode, ithusi lezinga eliphezulu kufanele lincibilikiswe ku-asidi ukuze kukhiqizwe i-electrolyte yethusi. Lesi sixazululo se-electrolyte sipontshwa ema-drum acwiliswe kancane, ajikelezayo ashajwa ngogesi. Kula ma-drum, ifilimu encane yethusi ifakwa i-electrode. Le nqubo yaziwa nangokuthi i-plating.

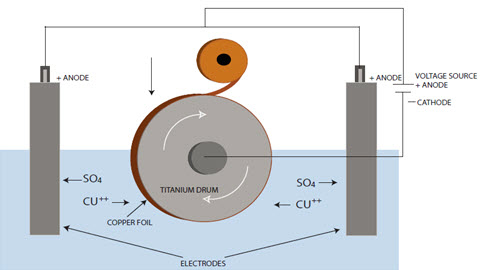

Enqubweni yokukhiqiza ithusi ebekwe nge-electrode, i-foil yethusi ifakwa esigubheni esijikelezayo se-titanium esivela esixazululweni sethusi lapho ixhunywe khona emthonjeni we-DC voltage. I-cathode inamathele esigubheni bese i-anode ifakwa esixazululweni se-electrolyte yethusi. Uma kusetshenziswa insimu kagesi, ithusi lifakwa esigubheni njengoba lijikeleza ngesivinini esiphansi kakhulu. Ubuso bethusi ohlangothini lwesigubhu bubushelelezi kanti uhlangothi oluphambene luqinile. Uma ijubane lesigubhu lihamba kancane, ithusi liba likhulu futhi okuphambene nalokho. Ithusi liyakhangwa futhi liqongelelwe ebusweni be-cathode besigubhu se-titanium. Uhlangothi olu-matte nolwesigubhu lwe-foil yethusi ludlula emijikelezweni ehlukene yokwelapha ukuze ithusi lifanelekele ukwenziwa kwe-PCB. Ukwelashwa kuthuthukisa ukunamathelana phakathi kwe-copper kanye ne-dielectric interlayer ngesikhathi senqubo ye-copper clad lamination. Enye inzuzo yokwelashwa ukusebenza njengezinto ezilwa nokungcoliswa ngokunciphisa i-oxidation yethusi.

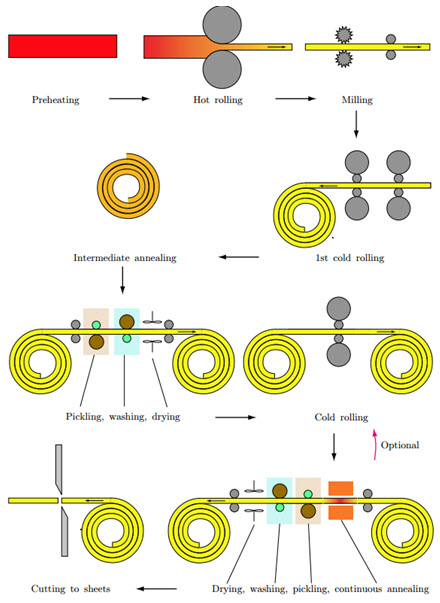

Umfanekiso 1:Inqubo Yokukhiqiza Ithusi Elifakwe Nge-ElectroIsithombe 2 sibonisa izinqubo zokukhiqiza imikhiqizo yethusi egoqiwe. Imishini yokugoqa ihlukaniswe cishe ngezinhlobo ezintathu; okungukuthi, izigayo zokugoqa ezishisayo, izigayo zokugoqa ezibandayo, kanye nezigayo ze-foil.

Amakhoyili ama-foil amancane ayakhiwa futhi aphathwe ngamakhemikhali nangomshini ngokulandelana aze akheke abe yisimo sawo sokugcina. Ukubuka konke kwenqubo yokugoqa ama-foil ethusi kunikezwe kuMfanekiso 2. Ibhulokhi yethusi eliphonswe (ubukhulu obucishe bube yi-5mx1mx130mm) lishiswa kufika ku-750°C. Bese, lishiswa ligoqwe ngokushintshashintsha ngezinyathelo eziningana liye phansi ku-1/10 yobukhulu balo bokuqala. Ngaphambi kokubanda kokuqala, izikali ezivela ekuphatheni ukushisa zisuswa ngokusila. Enqubweni yokugoqa ebandayo, ubukhulu buncishiswa bube yi-4 mm kanti amashidi akhiwa abe yi-coil. Inqubo ilawulwa ngendlela yokuthi izinto ziba zinde kuphela futhi zingashintshi ububanzi bazo. Njengoba amashidi engeke akhiwe kakhulu kulesi simo (izinto zisebenze kanzima kakhulu) aphathwa ngokushisa futhi ashiswa cishe ku-550°C.

Isikhathi sokuthunyelwe: Agasti-13-2021