Ukuhlukaniswa kwe-foil yethusi ye-ED:

1. Ngokusho kokusebenza, i-ED copper foil ingahlukaniswa ngezinhlobo ezine: STD, HD, HTE kanye ne-ANN

2. Ngokusho kwamaphuzu aphezulu,I-foil yethusi ye-EDingahlukaniswa ngezinhlobo ezine: akukho ukwelashwa kwendawo kanye nokugqwala okuvimbelayo, ukwelashwa kwendawo yokulwa nokugqwala, ukucubungula kohlangothi olulodwa kanye nokuvimbela ukugqwala kabili.

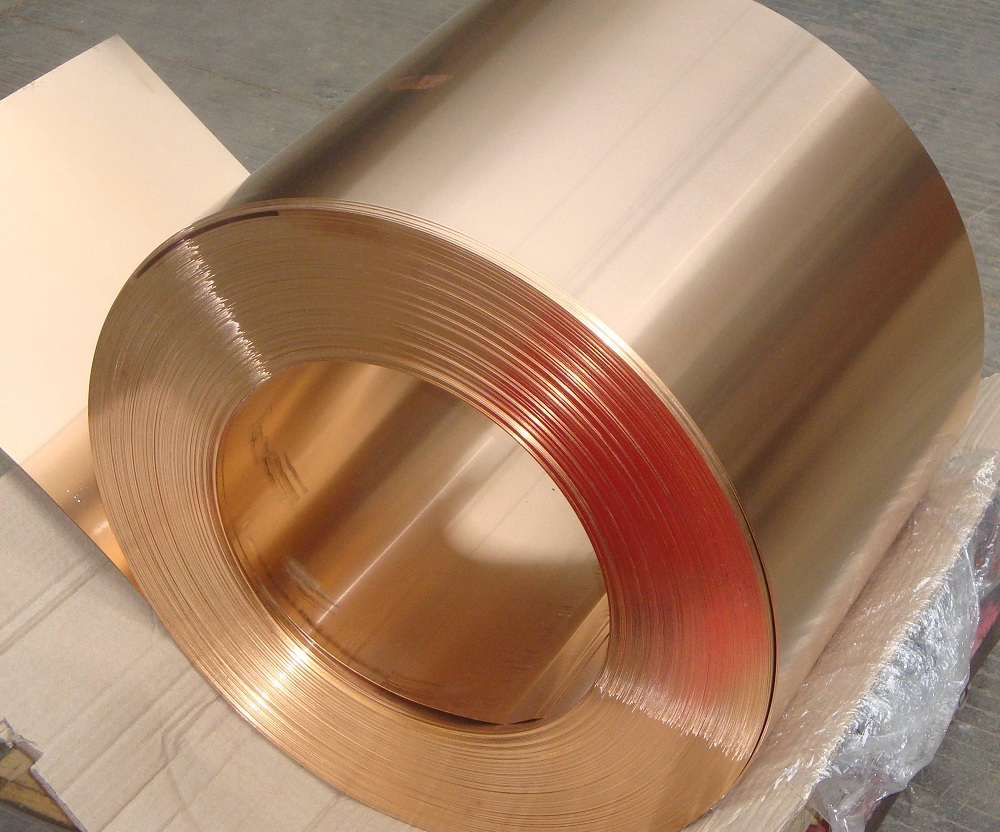

Kusukela ohlangothini lokujiya, ukujiya okulinganiselwe okungaphansi kuka-12μm kuyi-foil yethusi encane ye-electrolytic. Ukuze kugwenywe iphutha ekulinganisweni kokujiya, kanye nesisindo endaweni ngayinye kuvezwa njenge-foil yethusi ye-electrolytic engu-18 no-35μm, isisindo sayo esisodwa esihambisana no-153 no-305g / m2. Izindinganiso zekhwalithi ze-foil yethusi ye-ED kufaka phakathi ubumsulwa be-foil yethusi ye-electrolytic, ukumelana, amandla, ukunwebeka, ikhono lokushisela, ukugoba, ubulukhuni bendawo, njll.

3.I-foil yethusi ye-EDingahlukaniswa ngenqubo yokukhiqiza yokulungiselela isisombululo se-electrolytic, i-electrolysis kanye ne-post-processing ngokuya ngobuchwepheshe bokukhiqiza i-electrolytic copper foil.

Ukulungiswa kwe-electrolyte:

Okokuqala faka ubumsulwa obungaphezu kuka-99.8% wezinto zethusi ngemva kokususa amafutha ethangini elincibilikisiwe lethusi; bese upheka nge-sulfuric acid uvuselela bese sithola i-copper sulfate encibilikisiwe. Faka i-copper sulfate ethangini lapho ukuhlushwa kufinyelela izidingo. Kuzofika uhlelo lokujikeleza kwesisombululo ngepayipi kanye ne-pump reservoir kanye ne-cell Unicom. Ngemva kokuba ukujikeleza kwesisombululo kuzinzile, kunganika amandla i-electrolysis cell. I-Electrolyte idinga ukwengeza inani elifanele le-surfactant ukuqinisekisa amanani ethusi ancibilikisiwe, ukuma kwe-Crystal, ubulukhuni, i-porosity, nezinye izinkomba.

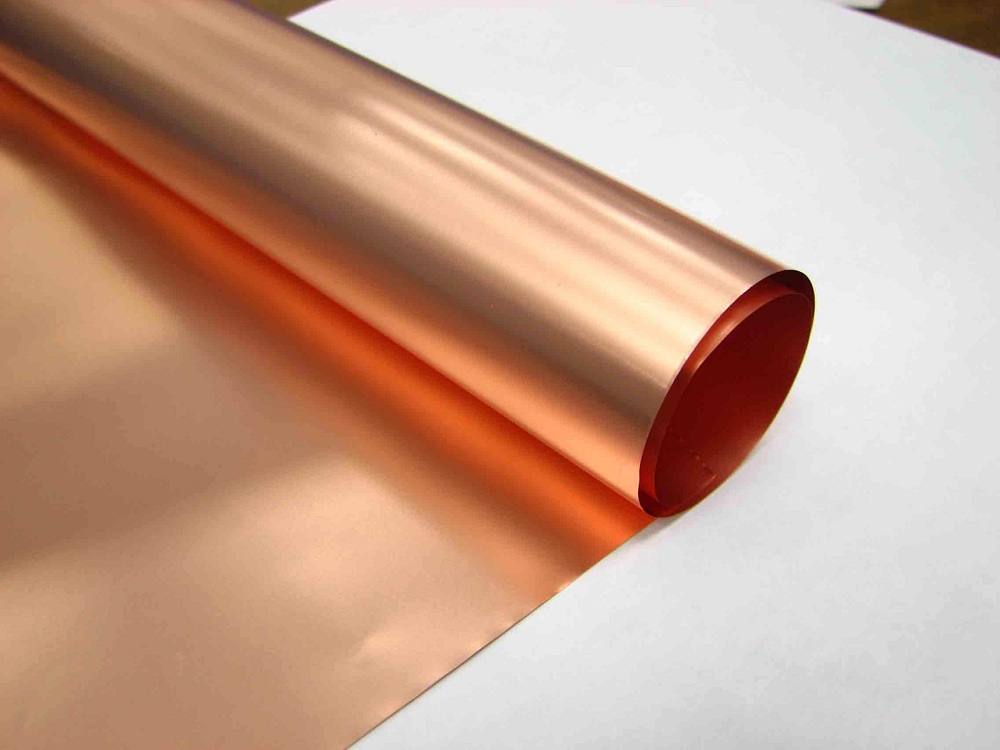

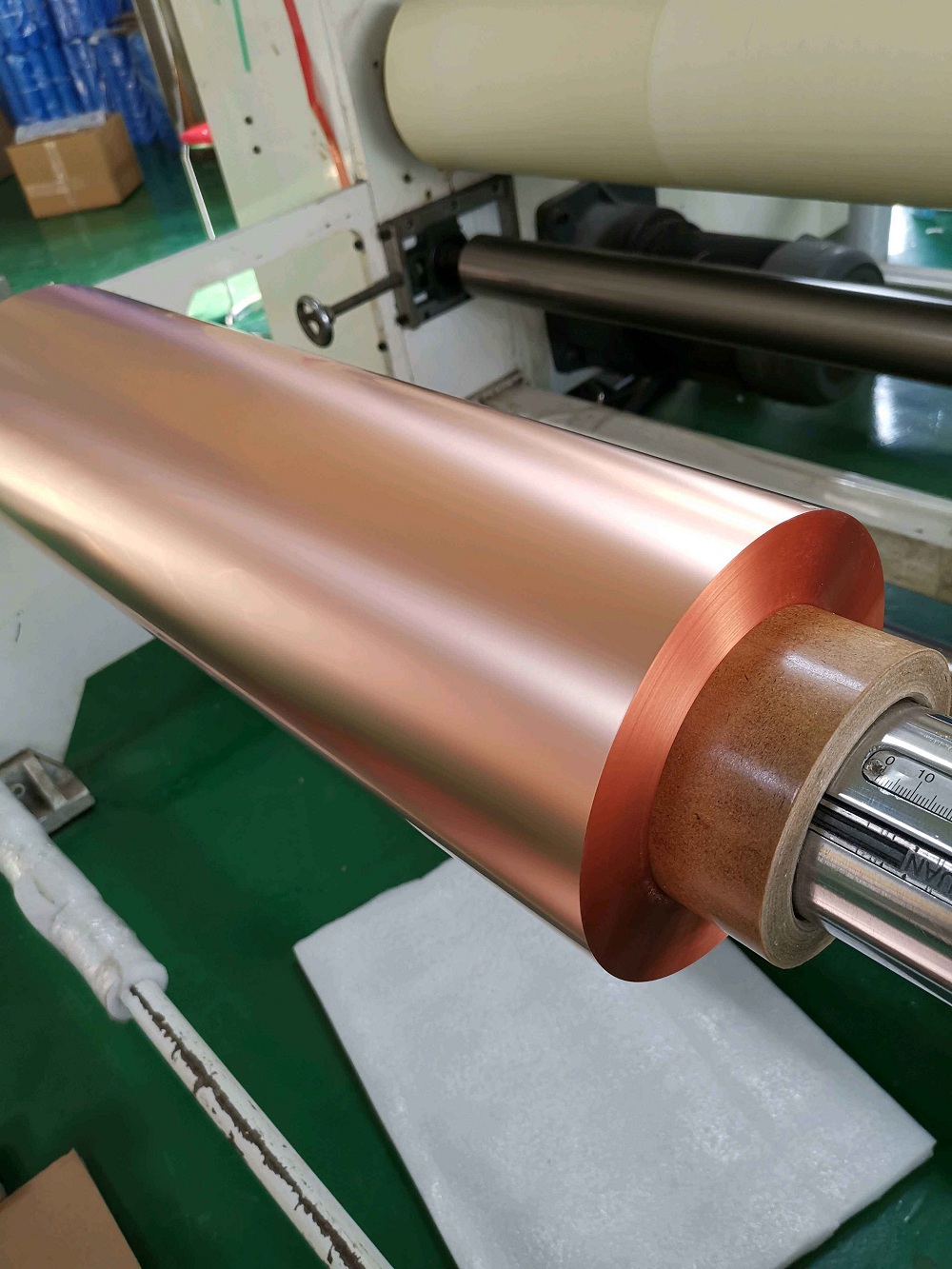

Inqubo yama-electrode kanye ne-electrolysis

I-Electrolysis cathode iyisigubhu esijikelezayo, esibizwa ngokuthi i-cathode roll. Futhi ingasebenzisa umucu wensimbi ongenakhanda otholakalayo njenge-cathode. Iqala ukufakwa ku-cathode yethusi ngemva kwamandla. Ngakho-ke, ububanzi besondo kanye nebhande kunquma ububanzi be-foil yethusi ye-electrolytic; futhi isivinini esijikelezayo noma esihambayo sinquma ukujiya kwe-foil yethusi ye-electrolytic. Ithusi elifakwe ku-cathode lihlutshwa njalo, lihlanzwe, lomiswe, lisikwe, ligoqwe futhi lihlolwe ngemva kokwelashwa okuthunyelwe kubafakizicelo abaphumelele. I-electrolysis anode ayincibiliki ku-lead noma i-lead alloy.

Ipharamitha yenqubo ayihlobene nje kuphela nesivinini se-electrolysis i-cathode, kodwa futhi nesisombululo se-electrolyte noma ukuhlushwa, izinga lokushisa, kanye nobuningi bamanje be-cathode ngesikhathi se-electrolysis.

Ipharamitha yenqubo ayihlobene nje kuphela nesivinini se-electrolysis i-cathode, kodwa futhi nesisombululo se-electrolyte noma ukuhlushwa, izinga lokushisa, kanye nobuningi bamanje be-cathode ngesikhathi se-electrolysis.

I-roller ye-titanium cathode spinning:

Ngenxa yokuthi i-titanium inokuqina okuphezulu kwamakhemikhali kanye namandla aphezulu. Ihlubuka kalula ebusweni bokugoqa kanye ne-porosity ephansi ye-electrolytic copper foil. I-titanium cathode enqubweni ye-electrolytic izokhiqiza i-passive phenomenon, ngakho-ke idinga ukuhlanzwa njalo, ukugaya, ukupholisha, i-nickel, i-chrome. Ama-corrosion inhibitors angangezwa futhi, njenge-nitro noma i-nitrous aromatic noma i-aliphatic compounds ku-electrolyte, izinga lokuphasiswa linciphisa i-titanium cathode. Ezinye izinkampani zisebenzisa i-cathode yensimbi engagqwali ukunciphisa izindleko.

Isikhathi sokuthunyelwe: Jan-09-2022