Imboni yezinto ze-PCB ichithe isikhathi esiningi ithuthukisa izinto ezinikeza ukulahleka kwesignali okuphansi kakhulu. Ngemiklamo yesivinini esiphezulu kanye nemvamisa ephezulu, ukulahleka kuzokhawulela ibanga lokusabalala kwesignali futhi kuphazamise izimpawu, futhi kuzodala ukuphambuka kwe-impedance okungabonakala ezilinganisweni ze-TDR. Njengoba siklama noma yiliphi ibhodi lesifunda eliphrintiwe futhi sakha amasekethe asebenza kumaza aphezulu, kungase kube nzima ukukhetha ithusi elibushelelezi kakhulu kuyo yonke imiklamo oyidalayo.

Nakuba kuyiqiniso ukuthi ukuba lukhuni kwethusi kudala ukuphambuka okwengeziwe kanye nokulahlekelwa kwe-impedance, ingabe i-foil yakho yethusi idinga ukuba bushelelezi kangakanani ngempela? Ingabe zikhona izindlela ezilula ongazisebenzisa ukunqoba ukulahlekelwa ngaphandle kokukhetha ithusi elibushelelezi kakhulu kuyo yonke idizayini? Sizobheka la maphuzu kulesi sihloko, kanye nokuthi yini ongayibheka uma uqala ukuthenga izinto ze-PCB stackup.

Izinhlobo zeI-PCB Copper Foil

Ngokuvamile uma sikhuluma ngethusi ezintweni ze-PCB, asikhulumi ngohlobo oluthile lwethusi, sikhuluma kuphela ngobulukhuni balo. Izindlela ezahlukene zokufaka ithusi zikhiqiza amafilimu anamanani ahlukene obulukhuni, angabonakala ngokucacile esithombeni se-scanning electron microscope (SEM). Uma uzosebenza kumaza aphezulu (ngokuvamile i-5 GHz WiFi noma ngaphezulu) noma ngesivinini esiphezulu, khona-ke naka uhlobo lwethusi oluchazwe kudathashethi yakho yezinto ezibonakalayo.

Futhi, qiniseka ukuthi uyaqonda incazelo yamanani e-Dk kudathashethi. Bukela le ngxoxo ye-podcast noJohn Coonrod waseRogers ukuze ufunde kabanzi mayelana nemininingwane ye-Dk. Unalokho engqondweni, ake sibheke ezinye zezinhlobo ezahlukene ze-PCB copper foil.

Kufakwe i-electrode

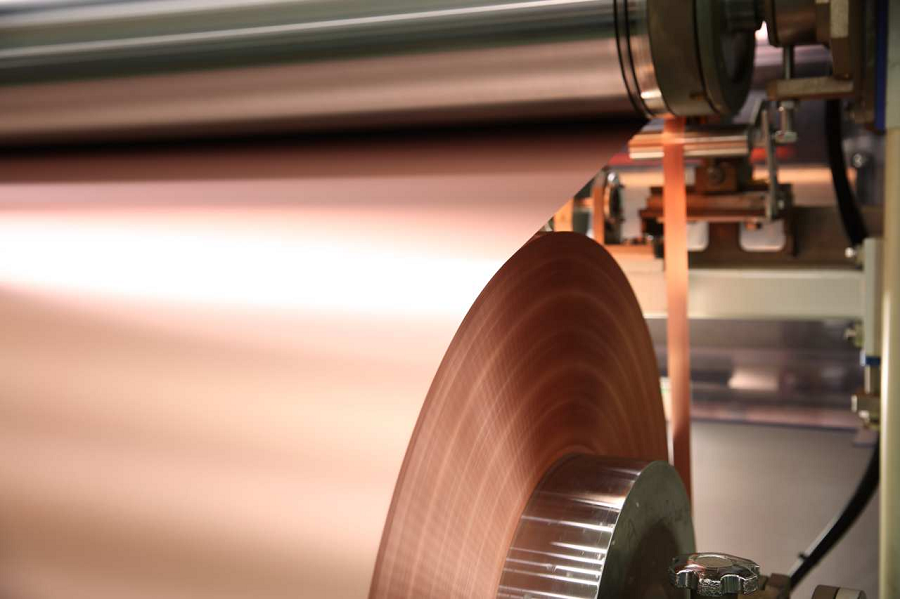

Kule nqubo, isigubhu siphendulwa ngesisombululo se-electrolytic, bese kusetshenziswa ukusabela kwe-electrodeposition "ukukhulisa" i-foil yethusi esigubheni. Njengoba isigubhu sijikeleza, ifilimu yethusi ephumayo igoqwa kancane kancane esigubheni, inikeze ishidi lethusi eliqhubekayo elingagoqwa kamuva esigubheni. Uhlangothi lwesigubhu lwethusi luzohambisana nobunzima besigubhu, kanti uhlangothi oluveziwe luzoba lukhuni kakhulu.

I-foil yethusi ye-PCB efakwe ngogesi

Ukukhiqizwa kwethusi okufakwe ngogesi.

Ukuze isetshenziswe enqubweni ejwayelekile yokwenziwa kwe-PCB, uhlangothi oluqinile lwethusi luzoqala luboshwe ku-dielectric yengilazi-resin. Ithusi elisele eliveziwe (uhlangothi lwesigubhu) kuzodingeka lihlungwe ngamabomu ngamakhemikhali (isb., ngokuqopha nge-plasma) ngaphambi kokuba lisetshenziswe enqubweni ejwayelekile yokubopha ithusi. Lokhu kuzoqinisekisa ukuthi lingaboshwa engqimbeni elandelayo ku-PCB stackup.

Ithusi Elifakwe Ama-Electroposed Eliphathwe Ngaphezulu

Angazi igama elihle kakhulu elihlanganisa zonke izinhlobo ezahlukene zokwelashwa kwendawoama-foil ethusi, ngakho-ke isihloko esingenhla. Lezi zinto zethusi zaziwa kakhulu ngokuthi ama-foil aphathwe ngendlela ephambene, yize kunezinye izinhlobo ezimbili ezitholakalayo (bheka ngezansi).

Ama-foil aphathwe ngokubuyela emuva asebenzisa ukwelashwa kwendawo okusetshenziswa ohlangothini olubushelelezi (ohlangothini lwedrama) lweshidi lethusi elibekwe nge-electrode. Isendlalelo sokwelashwa simane nje siwukumboza okuncane okubopha ithusi ngamabomu, ngakho-ke lizoba nokunamathela okukhulu ezintweni ze-dielectric. Lokhu kwelashwa kusebenza futhi njengesithiyo se-oxidation esivimbela ukugqwala. Uma leli thusi lisetshenziswa ukudala amaphaneli e-laminate, uhlangothi oluphathwe luboshelwe ku-dielectric, kanti uhlangothi olusele olugobile luhlala luveziwe. Uhlangothi oluveziwe ngeke ludinge ukugoba okwengeziwe ngaphambi kokuqopha; luzobe selunamandla anele okubopha ungqimba olulandelayo ku-PCB stackup.

Izinhlobo ezintathu ze-foil yethusi elashwe emuva zifaka:

I-foil yethusi ende yokushisa okuphezulu (HTE): Lena i-foil yethusi ebekwe nge-electrode ehambisana nezincazelo ze-IPC-4562 Grade 3. Ubuso obuveziwe buphathwa ngesithiyo se-oxidation ukuvimbela ukugqwala ngesikhathi sokugcina.

I-foil ephathwe kabili: Kuleli foil lethusi, ukwelashwa kusetshenziswa kuzo zombili izinhlangothi zefilimu. Lokhu okubalulekile ngezinye izikhathi kubizwa ngokuthi i-foil ephathwe nge-drum-side.

Ithusi elivikelayo: Lokhu akuvamile ukuhlukaniswa njengethusi eliphathwe phezulu. Le foil yethusi isebenzisa indwangu yensimbi ohlangothini olucwebezelayo lwethusi, bese iqiniswa ibe sezingeni elifunekayo.

Ukusetshenziswa kokwelashwa kwendawo kulezi zinto zethusi kulula: i-foil igoqwa ngokusebenzisa amabhati e-electrolyte engeziwe afaka i-copper plating yesibili, kulandelwe ungqimba lwembewu oluvimbelayo, bese ekugcineni ungqimba lwefilimu olulwa nokugqwala.

I-foil yethusi ye-PCB

Izinqubo zokwelapha ubuso be-foil yethusi. [Umthombo: UPytel, Steven G., et al. "Ukuhlaziywa kokwelashwa kwethusi kanye nemiphumela ekusakazweni kwesignali." Ngo-2008 i-58th Electronic Components and Technology Conference, amakhasi 1144-1149. IEEE, 2008.]

Ngalezi zinqubo, unezinto ezingasetshenziswa kalula enqubweni ejwayelekile yokwenziwa kwebhodi ngokucubungula okuncane okwengeziwe.

Ithusi Eligoqiwe Elihlanganisiwe

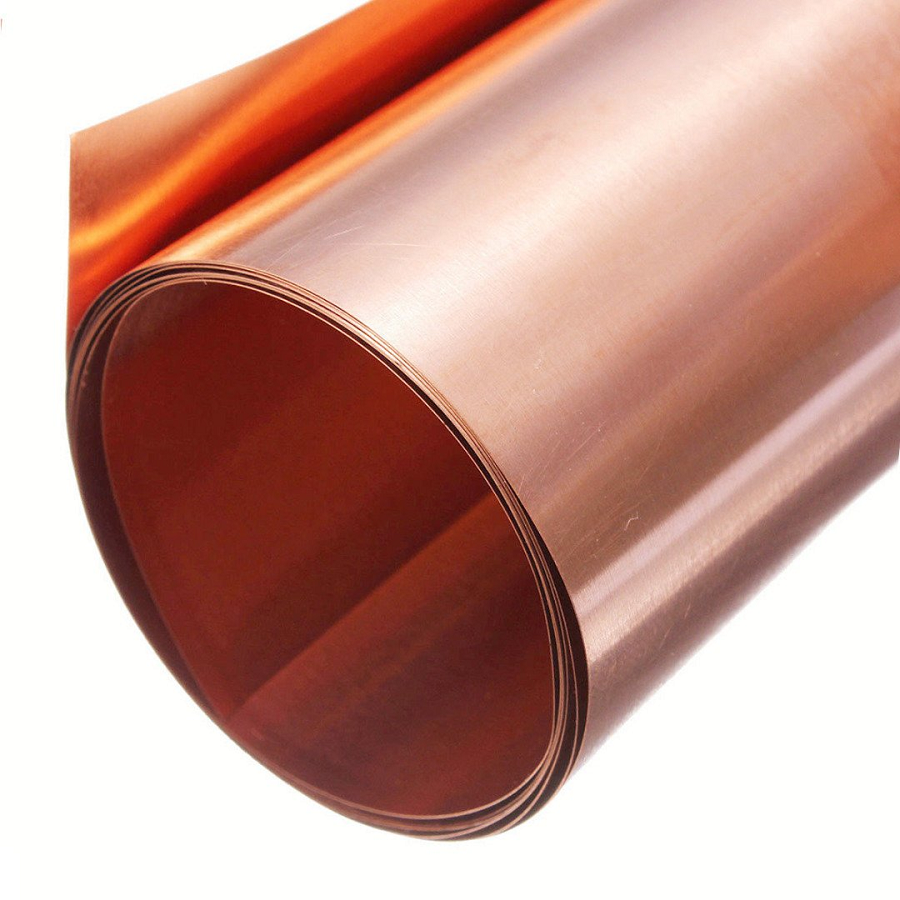

Ama-foil ethusi aqoqwe nge-anneal azodlulisa umqulu we-foil yethusi ngama-roller amabili, azogoqa ishidi lethusi ngokulibazisa liye ekujikeni okufunwayo. Ubulukhuni beshidi le-foil eliphumayo buzohluka kuye ngamapharamitha okugoqa (isivinini, ingcindezi, njll.).

Ishidi eliphumayo lingaba bushelelezi kakhulu, futhi imivimbo iyabonakala ebusweni beshidi lethusi eligoqiwe. Izithombe ezingezansi zibonisa ukuqhathanisa phakathi kwe-foil yethusi ebekwe nge-electrode kanye ne-foil egoqiwe.

Ukuqhathaniswa kwe-PCB yethusi foil

Ukuqhathaniswa kwama-foil afakwe i-electrodeposition vs. ama-rolled-annealed foil.

Ithusi Eliphansi

Lokhu akulona ngempela uhlobo lwe-foil yethusi ongalwenza ngenqubo ehlukile. I-Copper enephrofayili ephansi yi-copper ene-electrode ephathwa futhi iguqulwe ngenqubo ye-micro-roughening ukuze inikeze ubulukhuni obuphansi kakhulu obune-roughening eyanele yokunamathela kwi-substrate. Izinqubo zokukhiqiza la ma-foil ethusi ngokuvamile ziyimfihlo. Lawa ma-foil avame ukuhlukaniswa njenge-ultra-low profile (ULP), i-very low profile (VLP), kanye ne-low-profile nje (LP, cishe i-1 micron average roughness).

Izihloko ezihlobene:

Kungani kusetshenziswa i-Copper Foil ekukhiqizweni kwe-PCB?

I-Copper Foil Esetshenziswa Ebhodini Lesekethe Eliphrintiwe

Isikhathi sokuthunyelwe: Juni-16-2022