Ifoyili yethusiinezinga eliphansi le-oxygen ebusweni futhi ingaxhunywa ngezinhlobo ezahlukene ze-substrate, njengensimbi, izinto zokuvikela. Futhi i-foil yethusi isetshenziswa kakhulu ekuvikeleni nge-electromagnetic kanye ne-antistatic. Ukubeka i-foil yethusi eqhubayo ebusweni be-substrate futhi ihlanganiswe ne-substrate yensimbi, izohlinzeka ngokuqhubeka okuhle kakhulu kanye nokuvikela nge-electromagnetic. Ingahlukaniswa kanje: i-foil yethusi ezinamathelayo, i-foil yethusi eseceleni elilodwa, i-foil yethusi eseceleni eliphindwe kabili nokunye okunjalo.

Kulesi sigaba, uma uzofunda kabanzi nge-copper foil enqubweni yokukhiqiza i-PCB, sicela uhlole futhi ufunde okuqukethwe okungezansi kulesi sigaba ukuze uthole ulwazi olwengeziwe lobuchwepheshe.

Yiziphi izici ze-foil yethusi ekukhiqizweni kwe-PCB?

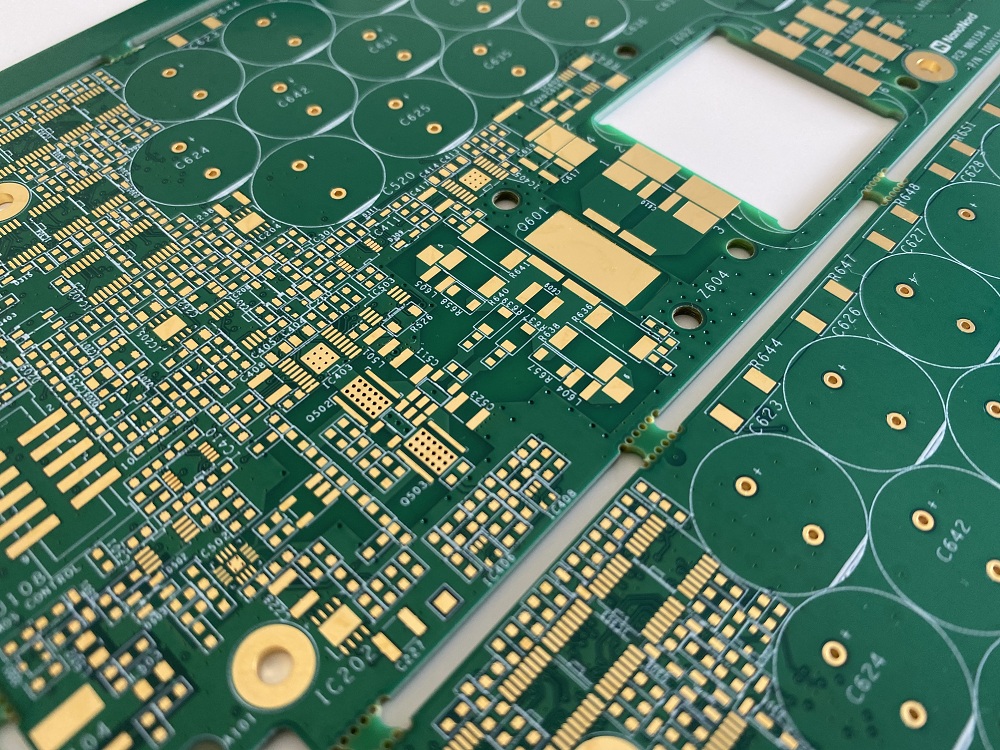

I-foil yethusi ye-PCBUbukhulu bethusi bokuqala obusetshenziswa ezingqimbeni zangaphandle nezangaphakathi zebhodi le-PCB elinezingqimba eziningi. Isisindo sethusi sichazwa njengesisindo (ngama-ounces) sethusi esikhona endaweni eyodwa yesikwele. Le pharamitha ikhombisa ubukhulu bethusi obuphelele kuleso sendlalelo. I-MADPCB isebenzisa izisindo zethusi ezilandelayo ekwenzeni i-PCB (ipuleti langaphambi kokufakwa). Izisindo ezilinganiswa ngo-oz/ft2. Isisindo sethusi esifanele singakhethwa ukuze sivumelane nesidingo somklamo.

· Ekukhiqizweni kwe-PCB, ama-foil ethusi asemiqulwini, okuyizinga le-elekthronikhi elihlanzekile elingu-99.7%, kanye nobukhulu obungu-1/3oz/ft2 (12μm noma 0.47mil) – 2oz/ft2 (70μm noma 2.8mil).

· I-foil yethusi inezinga eliphansi le-oxygen engaphezulu futhi inganamatheliswa kusengaphambili ngabakhiqizi be-laminate ezintweni eziyisisekelo ezahlukahlukene, njenge-metal core, i-polyimide, i-FR-4, i-PTFE kanye ne-ceramic, ukuze kukhiqizwe ama-laminate ambozwe ngethusi.

· Ingafakwa futhi ebhodini elinezingqimba eziningi njenge-foil yethusi uqobo ngaphambi kokucindezela.

· Ekwenziweni kwe-PCB okuvamile, ukujiya kokugcina kwethusi ezingqimbeni zangaphakathi kusale kwe-foil yethusi yokuqala; Ezingqimbeni zangaphandle sibeka ithusi elingeziwe elingu-18-30μm ezindleleni ngesikhathi senqubo yokufaka iphaneli.

· Ithusi lezendlalelo zangaphandle zamabhodi anezingqimba eziningi lisesimweni se-foil yethusi futhi licindezelwe ndawonye nama-prepregs noma ama-cores. Ukuze lisetshenziswe nama-microvias ku-HDI PCB, i-foil yethusi itholakala ngqo ku-RCC (ithusi elimbozwe nge-resin).

Kungani kudingeka i-foil yethusi ekukhiqizweni kwe-PCB?

I-foil yethusi yebanga le-elekthronikhi (ubumsulwa obungaphezu kuka-99.7%, ukujiya okungu-5um-105um) ingenye yezinto eziyisisekelo embonini yama-elekthronikhi. Ukuthuthukiswa okusheshayo komkhakha wolwazi lwe-elekthronikhi, ukusetshenziswa kwe-foil yethusi yebanga le-elekthronikhi kuyakhula, imikhiqizo isetshenziswa kabanzi kuma-calculator ezimboni, imishini yokuxhumana, imishini ye-QA, amabhethri e-lithium-ion, amasethi kamabonakude avamile, ama-video recorder, abadlali be-CD, ama-copier, ucingo, umoya opholile, ama-electronics ezimoto, ama-game consoles.

I-foil yethusi yezimboniingahlukaniswa ngezigaba ezimbili: i-foil yethusi egoqiwe (i-RA copper foil) kanye ne-point copper foil (ED copper foil), lapho i-calendar foil yethusi ine-ductility enhle nezinye izici, inqubo yokuqala yepuleti elithambile esetshenziswa i-Copper foil, kuyilapho i-electrolytic copper foil iyindleko ephansi yokukhiqiza i-copper foil. Njengoba i-rolling copper foil iyinto ebalulekile eluhlaza yebhodi elithambile, ngakho-ke izici ze-calendar copper foil kanye nezinguquko zamanani embonini yebhodi elithambile zinomthelela othile.

Yimiphi imithetho eyisisekelo yokuklama i-foil yethusi ku-PCB?

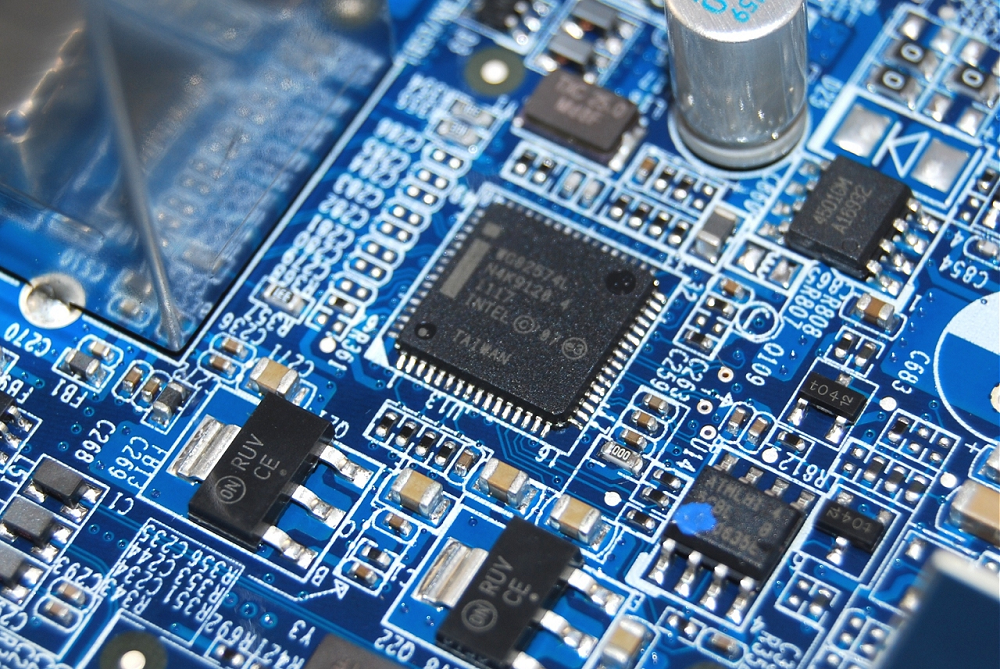

Uyazi ukuthi amabhodi wesekethe aphrintiwe avame kakhulu eqenjini lama-elekthronikhi? Ngiyaqiniseka ukuthi likhona kudivayisi kagesi oyisebenzisayo njengamanje. Kodwa-ke, ukusebenzisa lawa madivayisi kagesi ngaphandle kokuqonda ubuchwepheshe bawo kanye nendlela yokuklama nakho kuyinto evamile. Abantu basebenzisa amadivayisi kagesi njalo ngehora kodwa abazi ukuthi asebenza kanjani. Ngakho-ke nansi ezinye izingxenye eziyinhloko ze-PCB okukhulunywa ngazo ukuthi zinokuqonda okusheshayo kokuthi amabhodi wesekethe aphrintiwe asebenza kanjani.

· Ibhodi lesifunda eliphrintiwe liyibhodi lepulasitiki elilula elinokufakwa kwengilazi. I-foil yethusi isetshenziselwa ukulandelela izindlela futhi ivumela ukugeleza kwamacala kanye nezibonakaliso ngaphakathi kwedivayisi. Amacala ethusi ayindlela yokunikeza amandla ezingxenyeni ezahlukene zedivayisi kagesi. Esikhundleni sezintambo, amacala ethusi aqondisa ukugeleza kwamacala kuma-PCB.

· Ama-PCB angaba ungqimba olulodwa kanye nezingqimba ezimbili. I-PCB eyodwa enezingqimba iyona elula. Ine-foil yethusi kolunye uhlangothi kanti olunye uhlangothi luyindawo yezinye izingxenye. Ngesikhathi ku-PCB enezingqimba ezimbili, zombili izinhlangothi zigcinelwe i-foil yethusi. Ama-PCB ayinkimbinkimbi anezingqimba ezimbili anezinhlayiya eziyinkimbinkimbi zokugeleza kwamacala. Awekho ama-foil ethusi angawelana. Lawa ma-PCB ayadingeka kumadivayisi kagesi asindayo.

· Kukhona futhi izendlalelo ezimbili zama-solder kanye ne-silkscreen ku-PCB yethusi. I-solder mask isetshenziselwa ukuhlukanisa umbala we-PCB. Kunemibala eminingi yama-PCB atholakalayo njengoluhlaza okotshani, onsomi, obomvu, njll. I-Solder mask iphinda ichaze ithusi kwezinye izinsimbi ukuze kuqondwe ubunzima bokuxhumana. Nakuba i-silkscreen iyingxenye yombhalo we-PCB, izinhlamvu ezahlukene nezinombolo zibhalwa ku-silkscreen yomsebenzisi kanye nonjiniyela.

Ungayikhetha kanjani into efanele ye-foil yethusi ku-PCB?

Njengoba kushiwo ngaphambili, udinga ukubona indlela yesinyathelo ngesinyathelo yokuqonda iphethini yokukhiqiza yebhodi lesifunda eliphrintiwe. Ukwenziwa kwala mabhodi kuqukethe izendlalelo ezahlukene. Ake siqonde lokhu ngokulandelana:

Izinto ezingaphansi komhlaba:

Isisekelo esiyisisekelo phezu kwebhodi lepulasitiki eliqiniswa ngengilazi yi-substrate. I-substrate iyisakhiwo se-dielectric seshidi elivame ukwakhiwa ngama-epoxy resins kanye nephepha lengilazi. I-substrate yakhelwe ngendlela yokuthi ingahlangabezana nesidingo isibonelo izinga lokushisa lokuguquguquka (TG).

Ukuvikela:

Njengoba kusobala egameni, i-lamination iyindlela yokuthola izakhiwo ezidingekayo njengokwanda kokushisa, amandla okusika, kanye nokushisa kokuguquka (TG). I-lamination yenziwa ngaphansi kwengcindezi ephezulu. I-lamination kanye ne-substrate ndawonye kudlala indima ebalulekile ekugelezeni kwamacala kagesi ku-PCB.

Isikhathi sokuthunyelwe: Juni-02-2022