Amabhodi wesekethe aphrintiwe ayizingxenye ezidingekayo zamadivayisi amaningi kagesi. Ama-PCB anamuhla anezendlalelo eziningana: i-substrate, ama-traces, i-solder mask, kanye ne-silkscreen. Enye yezinto ezibaluleke kakhulu kwi-PCB ithusi, futhi kunezizathu eziningana zokuthi kungani kusetshenziswa ithusi esikhundleni sezinye izinhlobo ezifana ne-aluminium noma i-tin.

Zenziwe Ngani Ama-PCB?

Ngokusho kwenkampani yokuhlanganisa i-PCB, ama-PCB enziwe ngento ebizwa ngokuthi i-substrate, eyenziwe nge-fiberglass eqiniswe nge-epoxy resin. Ngaphezulu kwe-substrate kukhona ungqimba lwe-foil yethusi olungaboshwa nhlangothi zombili noma olulodwa kuphela. Uma i-substrate isiyenziwe, abakhiqizi babeka izingxenye kuyo. Basebenzisa imaski ye-solder kanye ne-silkscreen kanye nama-resistor, ama-capacitor, ama-transistors, ama-diode, ama-circuit chips, nezinye izingxenye ezikhethekile kakhulu.

Kungani Kusetshenziswa I-Copper Foil kuma-PCB?

Abakhiqizi be-PCB basebenzisa ithusi ngoba linomoya ophakeme kagesi nokushisa. Njengoba ugesi uhamba kanye ne-PCB, ithusi ligcina ukushisa kungalimazi futhi kucindezele yonke i-PCB. Ngezinye izinhlobo ze-alloy - njenge-aluminium noma i-tin - i-PCB ingashisa ngokungalingani futhi ingasebenzi kahle.

Ithusi liyingxube ekhethwayo ngoba lingathumela izimpawu zikagesi kulo lonke ibhodi ngaphandle kwezinkinga zokulahlekelwa noma ukwehlisa ijubane likagesi. Ukusebenza kahle kokudluliselwa kokushisa kuvumela abakhiqizi ukuthi bafake ama-heat sink akudala ebusweni. Ithusi ngokwalo liyasebenza kahle, njengoba i-ounce yethusi lingamboza i-PCB substrate engamamitha ayizikwele ayi-1.4 intshi noma ama-micrometer angu-35 ubukhulu.

Ithusi linamandla okuhambisa ugesi kakhulu ngoba line-electron yamahhala engahamba isuka kwelinye i-athomu iye kwelinye ngaphandle kokunciphisa. Ngenxa yokuthi lihlala lisebenza kahle kulelo zinga elincane kakhulu njengoba lisebenza emazingeni amakhulu, ithusi elincane lihamba ibanga elide.

Ithusi Nezinye Izinsimbi Eziyigugu Ezisetshenziswa Kuma-PCB

Abantu abaningi bayazi ukuthi ama-PCB aluhlaza. Kodwa, ngokuvamile anemibala emithathu ongqimbeni lwangaphandle: igolide, isiliva, kanye nobomvu. Anethusi elimsulwa ngaphakathi nangaphandle kwe-PCB. Ezinye izinsimbi ebhodini lesifunda zivela ngemibala ehlukahlukene. Ungqimba lwegolide lubiza kakhulu, ungqimba lwesiliva lunezindleko zesibili eziphakeme, kanti ubomvu lungqimba olungabizi kakhulu.

Ukusebenzisa i-Immersion Gold kuma-PCB

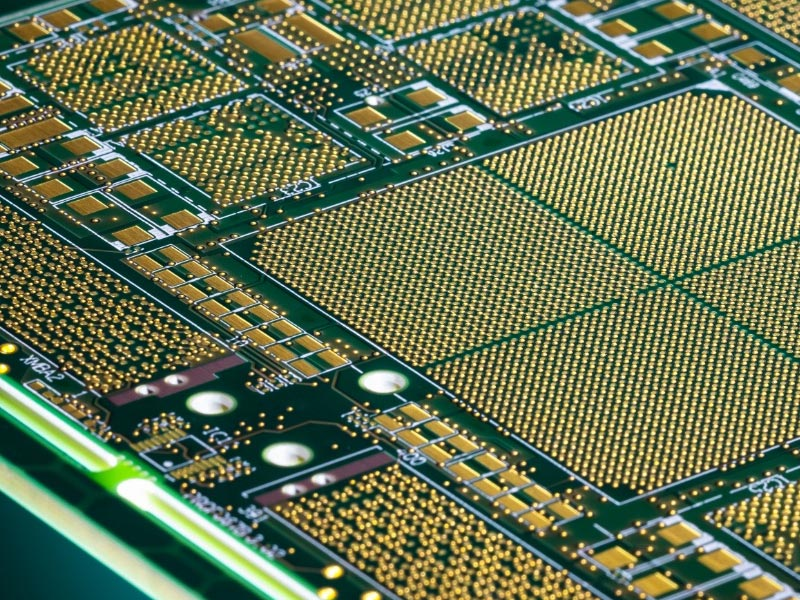

ithusi ebhodini lesifunda eliphrintiwe

Ingqimba eboshwe ngegolide isetshenziselwa izixhumi zokuxhuma kanye nama-component pads. Ingqimba yegolide yokucwilisa ikhona ukuvimbela ukufuduka kwama-athomu angaphezulu. Ingqimba ayiyona nje igolide ngombala, kodwa yenziwe ngegolide langempela. Igolide lincane kakhulu kodwa lanele ukwandisa isikhathi sokuphila kwezingxenye ezidinga ukushintshwa. Igolide livimbela izingxenye ze-solder ukuthi zibole ngokuhamba kwesikhathi.

Ukusebenzisa i-Immersion Silver kuma-PCB

Isiliva lingenye insimbi esetshenziswa ekukhiqizweni kwe-PCB. Lishibhile kakhulu kunokucwiliswa kwegolide. Ukucwiliswa kwesiliva kungasetshenziswa esikhundleni sokucwiliswa kwegolide ngoba kusiza nasekuxhumekeni, futhi kunciphisa izindleko eziphelele zebhodi. Ukucwiliswa kwesiliva kuvame ukusetshenziswa kuma-PCB asetshenziswa ezimotweni nasezintweni ezisetshenziswa yikhompyutha.

I-Copper Clad Laminate kuma-PCB

Esikhundleni sokusebenzisa ukucwilisa, ithusi lisetshenziswa ngendlela embozwe ngendwangu. Lolu ungqimba olubomvu lwe-PCB, futhi luyinsimbi esetshenziswa kakhulu. I-PCB yenziwe ngethusi njengensimbi eyisisekelo, futhi kuyadingeka ukwenza amasekethe axhumane futhi akhulumisane ngempumelelo.

Isetshenziswa Kanjani I-Copper Foil kuma-PCB?

Ithusi linokusetshenziswa okuningana kuma-PCB, kusukela ku-laminate embozwe ngethusi kuya kuma-traces. Ithusi libalulekile ukuze ama-PCB asebenze kahle.

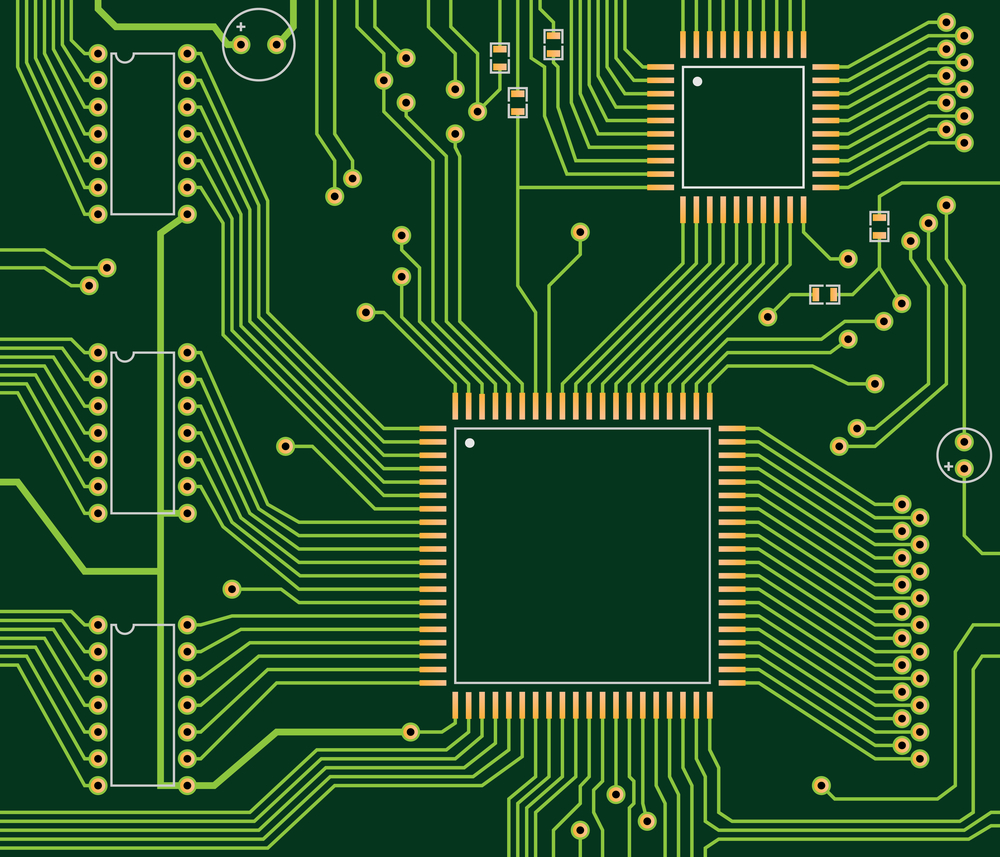

Kuyini i-PCB Trace?

I-trace ye-PCB yilokho ezwakala ngakho, indlela okufanele ilandelwe yisekethe. I-trace ihlanganisa inethiwekhi yethusi, izintambo, kanye nokushisa, kanye nama-fuse kanye nezingxenye ezisetshenziswa ebhodini.

Indlela elula yokuqonda umkhondo uwukucabanga njengomgwaqo noma ibhuloho. Ukuze kuhlangatshezwane nezimoto, umkhondo udinga ukuba banzi ngokwanele ukubamba okungenani ezimbili zazo. Kudingeka ube mkhulu ngokwanele ukuze ungawi ngaphansi kwengcindezi. Kudingeka futhi wenziwe ngezinto ezizomelana nesisindo sezimoto ezihamba kuwo. Kodwa, umkhondo wenza konke lokhu ngezinga elincane kakhulu ukuhambisa ugesi kunezimoto.

Izingxenye ze-PCB Trace

Kunezingxenye eziningana ezakha i-PCB trace. Zinemisebenzi ehlukahlukene okudingeka yenziwe ukuze ibhodi lenze umsebenzi walo ngokwanele. Ithusi kufanele lisetshenziswe ukusiza ama-trace ukuthi enze imisebenzi yawo, futhi ngaphandle kwe-PCB, besingeke sibe namadivayisi kagesi. Cabanga ngezwe elingenazo ama-smartphone, ama-laptop, abenzi bekhofi, nezimoto. Yilokho ebesiyoba nakho ukube ama-PCB abengasebenzisi ithusi.

Ubukhulu be-PCB Trace

Umklamo we-PCB uncike ekujiyeni kwebhodi. Ukujiya kuzothinta ibhalansi futhi kuzogcina izingxenye zixhunyiwe.

Ububanzi Bokulandelela kwe-PCB

Ububanzi bomkhondo bubalulekile futhi. Lokhu akuthinti ibhalansi noma ukunamathela kwezingxenye, kodwa kugcina ugesi udlula ngaphandle kokushisa ngokweqile noma ukulimaza ibhodi.

I-PCB Trace yamanje

Ugesi we-PCB trace uyadingeka ngoba yilokhu okusetshenziswa yibhodi ukuhambisa ugesi ngezingxenye kanye nezintambo. Ithusi liyasiza lokhu, futhi i-electron yamahhala ku-athomu ngayinye yenza ugesi uhambe kahle phezu kwebhodi.

Kungani i-Copper Foil ikwi-PCB

Inqubo Yokwenza Ama-PCB

Inqubo yokwenza i-PCB iyafana. Ezinye izinkampani zikwenza ngokushesha kunezinye, kodwa zonke zisebenzisa inqubo nezinto ezifanayo. Lezi yizinyathelo:

Yenza isisekelo nge-fiberglass nama-resin

Beka izendlalelo zethusi esisekelweni

Khomba futhi usethe amaphethini ethusi

Geza ibhodi ebhavini

Faka imaski yokuvikela ukuze uvikele i-PCB

Namathisela isikrini se-silkscreen ku-PCB

Beka futhi uhlanganise ama-resistor, amasekethe ahlanganisiwe, ama-capacitor, nezinye izingxenye

Hlola i-PCB

Ama-PCB kudingeka abe nezingxenye ezikhethekile kakhulu ukuze asebenze kahle. Esinye sezakhi ezibaluleke kakhulu ze-PCB yithusi. Le ngxube iyadingeka ukuze kuqhutshwe ugesi kumadivayisi lapho ama-PCB azofakwa khona. Ngaphandle kwethusi, amadivayisi ngeke asebenze ngoba ugesi ngeke ube nengxube yokuhamba.

Isikhathi sokuthunyelwe: Ephreli-25-2022