I-ED Copper Foils ye-FPC

Isingeniso Somkhiqizo

I-Electrolytic copper foil ye-FPC ithuthukiswe ngokukhethekile futhi yenzelwe imboni ye-FPC (FCCL).Le foil yethusi ye-electrolytic ine-ductility engcono, i-roughness ephansi namandla angcono wepebula kunamanye ama-copper foil.Ngesikhathi esifanayo, ukuqeda phezulu kanye nokuqina kwe-foil yethusi kungcono futhi ukumelana nokugoqa nakho kungcono kunemikhiqizo ye-foil yethusi efanayo.Njengoba le foil yethusi isekelwe kwinqubo ye-electrolytic, ayiqukethe amafutha, okwenza kube lula ukuhlanganiswa nezinto ze-TPI emazingeni okushisa aphezulu.

Ububanzi be-Dimension

Ubukhulu: 9µm~35µm

Imisebenzi

Ingaphezulu lomkhiqizo limnyama noma libomvu, linobulukhuni obungaphansi.

Izinhlelo zokusebenza

I-Flexible Copper Clad Laminate (FCCL), Fine Circuit FPC, ifilimu elincanyana lekristalu elihlanganiswe ne-LED.

Izici

Ukuminyana okuphezulu, ukumelana nokugoba okuphezulu nokusebenza okuhle kwe-etching.

I-Microstructure

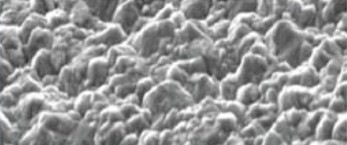

I-SEM(Ngaphambi Kokwelashwa Okungaphezulu)

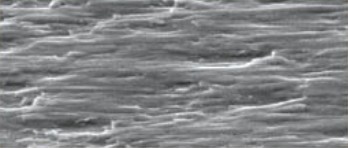

I-SEM(Uhlangothi Olucwebezelayo Ngemva Kokwelashwa)

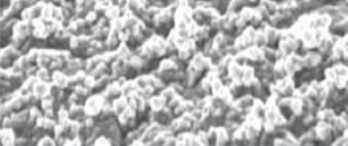

I-SEM(Uhlangothi Oluqinile Ngemva Kokwelashwa)

Ithebula1- Ukusebenza (GB/T5230-2000、IPC-4562-2000)

| Ukwahlukanisa | Iyunithi | 9mm | 12μm | 18mm | 35μm | |

| Cu Okuqukethwe | % | ≥99.8 | ||||

| Isisindo Sendawo | g/m2 | 80±3 | 107±3 | 153±5 | 283±7 | |

| Amandla Okuqina | I-RT(23℃) | Kg/mm2 | ≥28 | |||

| I-HT(180℃) | ≥15 | ≥15 | ≥15 | ≥18 | ||

| Ukwelula | I-RT(23℃) | % | ≥5.0 | ≥5.0 | ≥6.0 | ≥10 |

| I-HT(180℃) | ≥6.0 | ≥6.0 | ≥8.0 | ≥8.0 | ||

| Ubulukhuni | Shiny(Ra) | μm | ≤0.43 | |||

| I-Matte(Rz) | ≤2.5 | |||||

| Amandla e-Peel | I-RT(23℃) | Kg/cm | ≥0.77 | ≥0.8 | ≥0.8 | ≥0.8 |

| Izinga elehlisiwe le-HCΦ(18%-1hr/25℃) | % | ≤7.0 | ||||

| Ukushintsha kombala(E-1.0hr/200℃) | % | Kuhle | ||||

| I-Solder Floating 290 ℃ | Isiqephu | ≥20 | ||||

| Ukubukeka(Ibala kanye nempushana yethusi) | ---- | Lutho | ||||

| Iphinikhodi | EA | Uziro | ||||

| Ukubekezelela Usayizi | Ububanzi | mm | 0 ~ 2mm | |||

| Ubude | mm | ---- | ||||

| Ingqikithi | Mm/intshi | Ngaphakathi Ububanzi 79mm/3 inch | ||||

Qaphela:1. Ukusebenza kokumelana ne-copper foil oxidation kanye ne-surface density index kungaxoxiswana ngayo.

2. Inkomba yokusebenza ingaphansi kwendlela yethu yokuhlola.

3. Isikhathi sokuqinisekisa ikhwalithi yizinsuku ezingama-90 kusukela ngedethi etholwe ngayo.