I-RA Copper Foil

I-Foil yethusi egoqiwe

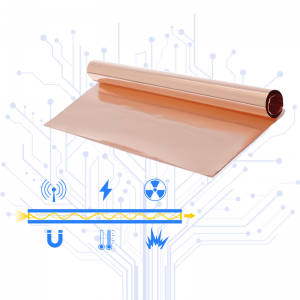

Izinto zensimbi ezinokuqukethwe okuphezulu kakhulu kwethusi zibizwa ngokuthi ithusi elimsulwa. Zivame ukwaziwa ngokuthiobomvu ithusi ngenxa yobuso bayo kuvelaumbala obomvu-onsomi. Ithusi linokuguquguquka okuphezulu kanye nokuguquguquka. Liphinde libe nokuqhuba okuhle kakhulu kukagesi nokushisa. I-foil yethusi ekhiqizwa yiInsimbi Ecwebezelayo hhayi nje kuphela ukuthi inezici zobumsulwa obuphezulu kanye nokungcola okuphansi, kodwa futhi ine-bushelelezi ukuqeda ubuso, ukuma kweshidi eliyisicaba kanye nokufana okuhle kakhulu. Zifanele ukusetshenziswa njengezinto zokuvikela zikagesi, ezishisayo kanye nezamandla kagesi. I-foil yethusi egoqiwe evelaInsimbi Ecwebezelayo futhi kulula kakhulu ukuyibumba nokuyifaka ethangeni. Ngenxa yokuthi iyindilingaisakhiwo ye-foil yethusi egoqiwe, isimo esithambile nesiqinile singalawulwa yinqubo yokubopha, okwenza ifaneleke kakhulu ezinhlobonhlobo eziningi izinhlelo zokusebenza.I-CIVEN METAL ingakhiqiza nama-foil ethusi ngobukhulu nobubanzi obuhlukene ngokwezidingo zamakhasimende, ngaleyo ndlela kunciphisa izindleko zokukhiqiza futhi kuthuthukiswe ukusebenza kahle kokucubungula.

| Izinto Eziyisisekelo | C11000 Ithusi, Cu > 99.90% |

| Ububanzi Bokujiya | 0.01mm-0.15mm (0.0004inch~0.006inch) |

| Ububanzi Bebanga | 4mm-400mm (0.16inch ~ 16inch) |

| Intukuthelo | Kuqinile, Kuqinile Ingxenye, Kuthambile |

| Isicelo | I-Transformer, Isixhumi Esiguquguqukayo Sethusi, i-CCL, i-FCCL, i-PCB, i-Geothermal Film, Ukwakhiwa, Ukuhlobisa njll. |

| GB | I-ALLOY CHA. | USAYIZI (mm) | ||||

| (I-ISO) | (ASMT) | (I-JIS) | (I-BIS) | (I-DIN) | ||

| T2 | I-Cu-ETP | C11000 | C1100 | C101 | R-Cu57 | Ubukhulu: 0.01-0.15/Ububanzi obukhulu: 400 |

| TU2 | I-Cu-OF | C10200 | C1020 | I-Cu-OFC | OF-Cu | |

Izakhiwo Zemishini

| Intukuthelo | I-JIS Temper | Amandla Okudonsa Rm/N/mm 2 | Ukuphakama okungu-A50/% | Ukuqina kwe-HV |

| M | O | 220~275 | ≥ 15 | 40~60 |

| Y2 | 1/4H | 240~300 | ≥ 9 | 55~85 |

| Y | H | 330~450 | - | 80~150 |

Qaphela: Singahlinzeka ngemikhiqizo enezinye izakhiwo ngokwezidingo zamakhasimende.

Izakhiwo Ezibonakalayo

| Ubuningi | 8.9g/cm3 |

| Ukuqhuba kukagesi (20°C) | ubuncane obungu-90% we-IACS wokufaka umoya opholileubuncane obungu-80% we-IACS we-rolled to temper |

| Ukushisa (20°C) | 390W/(m°C) |

| Imodulus enwebekayo | 118000N/m |

| Izinga lokushisa lokuthambisa | ≥380°C |

Osayizi kanye nokubekezelelana (mm)

| Ubukhulu | Ukubekezelelana Kokujiya | Ububanzi | Ukubekezelelana Kobubanzi |

| 0.01~0.015 | ± 0.002 | 4~250 | ± 0.1 |

| > 0.018~0.10 | ± 0.003 | 4~400 | |

| > 0.10~0.15 | ± 0.005 | 4~400 |

Imininingwane Iyatholakala (mm)

| Ubukhulu | Ububanzi | Intukuthelo |

| 0.01~0.015 | 4~250 | O,H |

| > 0.018~0.10 | 4~400 | O,H |

| > 0.10~0.15 | 4~400 | O,1/2H,H |

I-Carried Standard (Yakamuva)

| Izizwe | Inombolo Ejwayelekile | Igama Elijwayelekile |

| IShayina | GB/T2059--2000 | IZINGA LIKAZWELONKE LASE-CHINA |

| I-Japan | I-JIS H3100:2000 | AMASHIDI E-ALLOY ETHUSI NETHUSI, AMAPULETI NEZINCWADI |

| I-USA | I-ASTM B36/B 36M -01 | INCAZELO EJWAYELEKILE YETHUSI, IPULETI, ISHIDI, UKUQHAWULA NEBHA ELIGQIQWE |

| IJalimane | I-DIN-EN 1652:1997 | IPULETI, ISHIDI, UMQAQA NEZINDINGELA ZETHUSI NETHUSI NGEZINHLOSO EZIJWAYELEKILE |

| I-DIN-EN 1758:1997 | I-Strip ye-Alloys yethusi nethusi yamafreyimu e-lead | |

| I-SEMI | I-SEMI G4-0302 | INCAZELO YEZINTO EZINGU-LEADFRAME EZISETSHENZISWA EKUKHIQIZWENI KWAMA-LEADFRAME ANESITEMPU |

![[RTF] I-Reverse Treated ED Copper Foil](https://cdn.globalso.com/civen-inc/RTF-Reverse-Treated-ED-Copper-Foil-300x300.png)